Why Process Engineering?

With a deep understanding of the process, we collaborate closely with our clients to develop tailored solutions. This may involve implementing energy-efficient technologies, optimizing process parameters, and integrating renewable energy sources. Additionally, we emphasize waste reduction strategies, such as recycling and reusing by products.

Throughout the implementation phase, we continuously monitor and evaluate the performance of the updated process, ensuring that the desired efficiencies and environmental targets are met. Regular assessments and data-driven insights help us make necessary adjustments to further optimize operations and reduce carbon emissions.

By adopting this approach, we not only enhance operational efficiency and profitability for our clients but also contribute to a sustainable future by reducing their carbon footprint. Our commitment to process engineering goes beyond short-term gains, aiming to create long-lasting positive impacts on both business and the environment.

Process Engineering Services

Our process engineering services for optimization.

- Plant Design Engineering

- Process Optimization

- Advanced Automation Solutions

- Operations Bottleneck and Constraint Analysis

- Technical and Economic Project Evaluation

- Energy and Utilities Optimization

- Process Safety and Hazard Analysis

- Hygienic and Sanitary Design Solutions

- Clean In Place (CIP) Systems Design

- Balance of Plant Design and Optimization

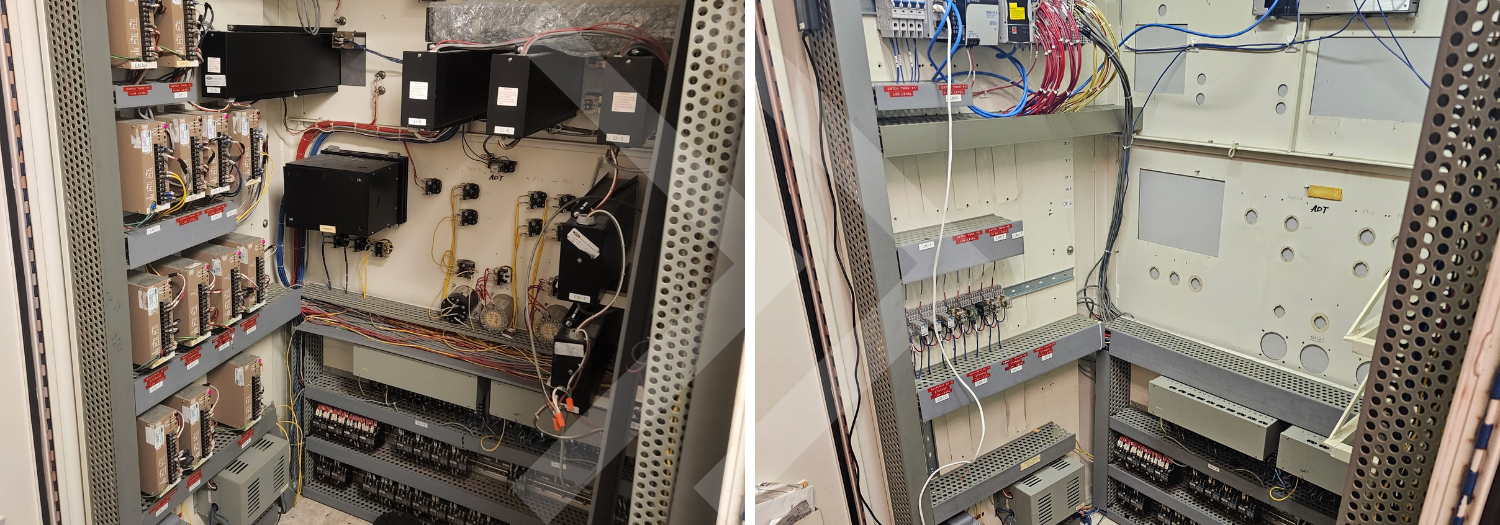

- Construction Field Support and Quality Oversight

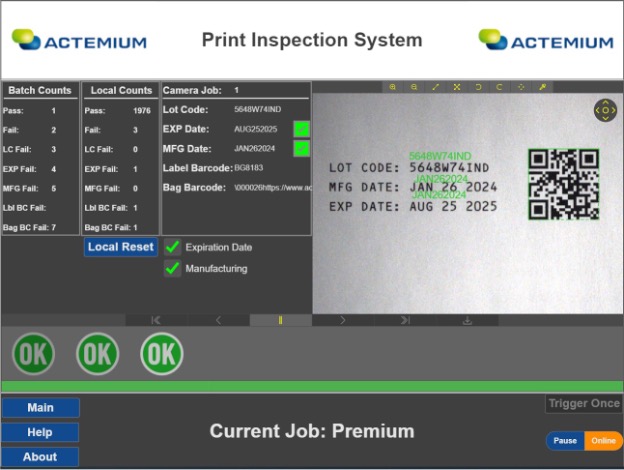

Batching S88

Inconsistency in batches and formulation causes a significant amount of extra work and scrap. It’s a top contributor to efficiency in the plant. Making a consistent product requires precise control of all aspects of the batch process. To tackle this problem, Actemium has developed a consistent batch solution and philosophy based upon common software standards, terminology, and control models. The ISA Batch Control Standard S88.01 provides a solid backdrop for Batching best practices with us dosing a little additional structure to address real world plant dynamics.

Our batching expertise has been recognized by some of the top S88 minds in Rockwell and AVEVA because of our practical application of their standard toolkit applications.

Regardless of the approach to batching that you choose, be it a PLC-based batch solution or a formal S88 application like AVEVA’s InBatch or Rockwell’s FTBatch, Actemium has the expertise to consistently deliver the “Golden Batch.”